Processes

Manufacturing the mixer

The mixer is the familiar device that enables us to safely access and control water, the essential element for our comfort and body care. That is the reason for Huber's constant commitment to mixers that ensure the highest reliability and precision, for optimal and long-lasting performance.

The manufacturing of a Cisal mixer starts with raw materials of the highest quality. Every single batch is guaranteed by a certificate of analysis and compliance.

The brass rods are machined on fully automated CNC lathes, operating 24/7 with the utmost precision.

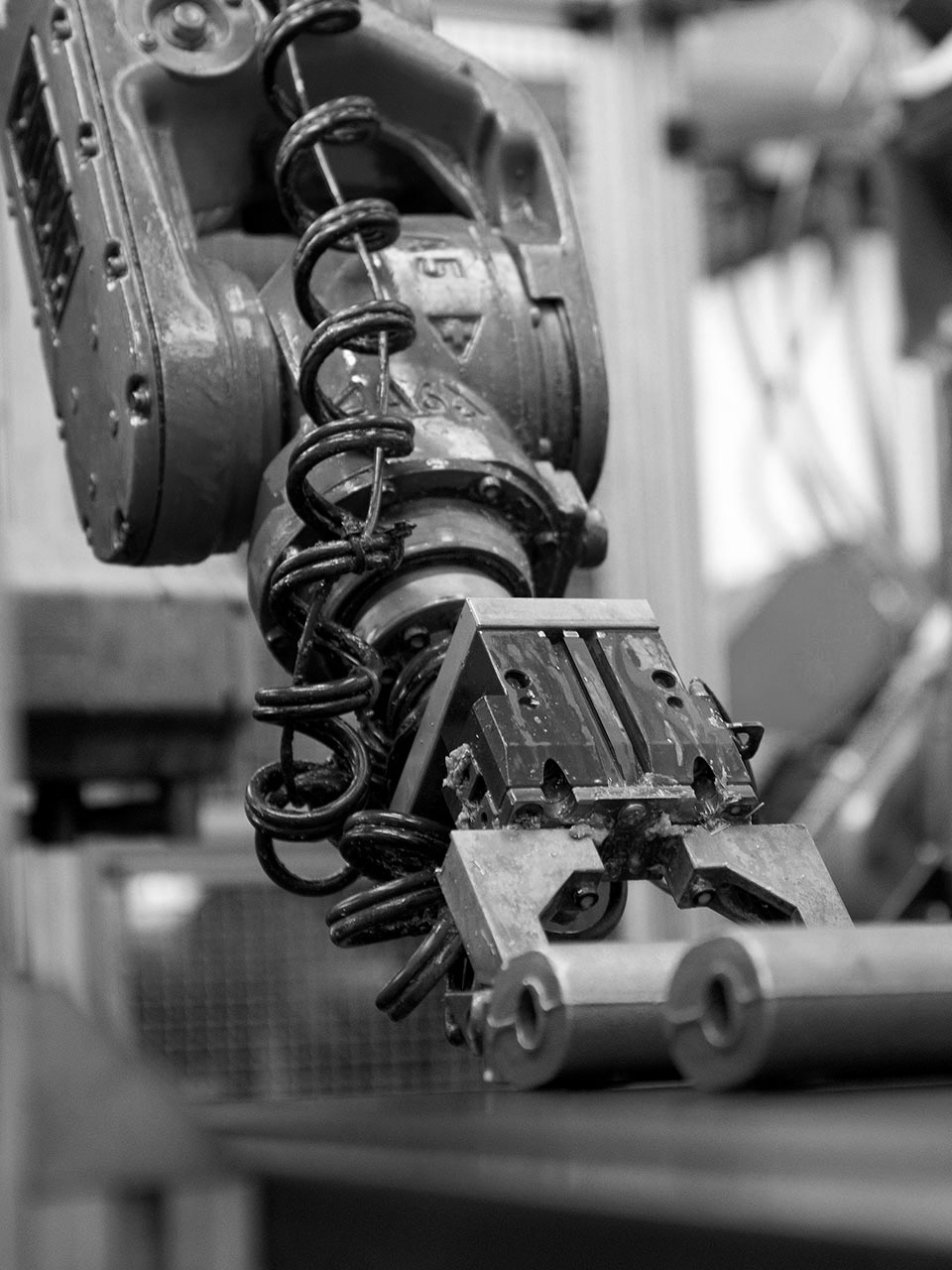

Mechanical machining on the mixers' bodies are performed by specialized transfer devices. The complete set of machining stages is carried out in a single cycle of simultaneous operations. All bodies are then 100% tested, one by one.

Once polished, the pieces are ready for the chrome-plating phase, which gives our mixers their high-thickness superficial protective coating and their shine.

Cisal thermostatic cartridges are entirely assembled in-house, and then tried, tested and temperature-calibrated one by one.

The assembly and single testing of all thermostatic mixers are carried out on integrated automatic lines, which guarantee precision and reliability by checking the performance of every single piece.

Dozen of quality tests are performed every day on finished mixers, in order to guarantee that Huber's strict requirements are always met.

…and they are finally ready to let you enjoy the comfort of your shower in complete safety.